Research

The Importance of Autonomous Research

In current materials development, the scope of material exploration is rapidly expanding,

making the development of efficient exploration methods highly desirable.

This expansion

is primarily due to two factors:

- An increase in the number of elements that constitute materials. When also considering the ratio of each element (composition), there are countless possibilities.

- The refinement of synthesis processes and measurement technologies, which has led to a greater diversity and higher resolution in experimental parameter control.

Traditionally, researchers and engineers have been responsible for materials design and optimizing synthesis conditions. Due to time and cost constraints, the scope of exploration was limited to a small fraction of a vast search space.

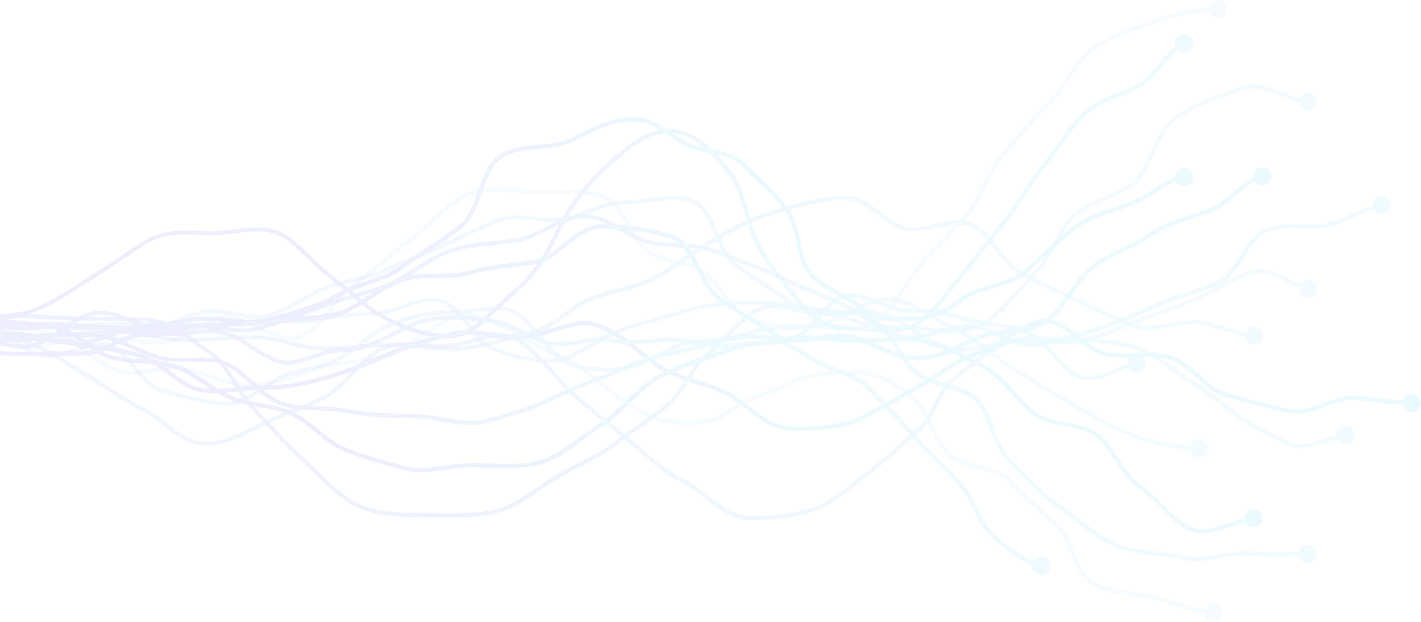

By establishing a new material research style leveraging machine learning and robotics, and integrating the intuition, know-how, and experience of master craftsmen and researchers, researchers can focus on high-value-added “creative work” and accelerate material research. We are now on the cusp of a major transformation in material research driven by machine learning and robotics.

A particularly crucial concept is "autonomous" research and development. In this process,

machine learning formulates experimental plans without human intervention, and robots

execute the experiments. The results are then registered in a database, and machine learning

technology devises the next experimental plan. This autonomous approach to research is

referred to as a closed-loop system.

However, a closed-loop system on its own leaves the

search space vast. To find the optimal material, it is essential to narrow down the search,

and this is where human intuition, know-how, and the expertise of master craftsmen come into

play. On this page, we will introduce pioneering examples of materials research that

integrate machine learning and robotics.

Research at the Hitosugi-Shimizu Laboratory

“Autonomous materials synthesis by machine learning and robotics”

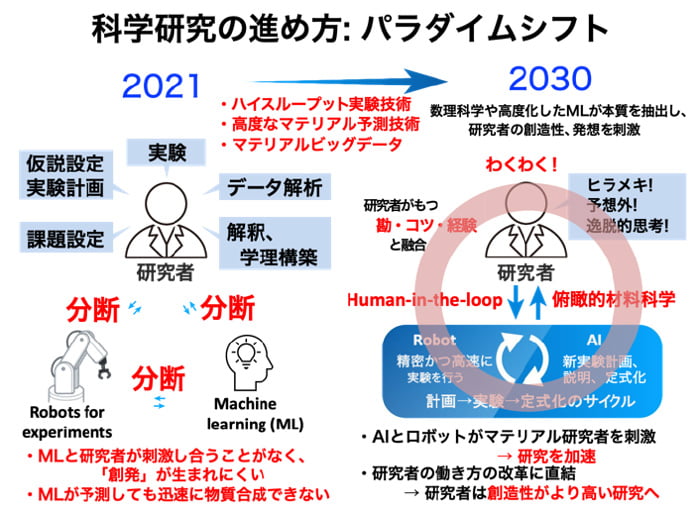

The Hitosugi & Shimizu Laboratory has developed a system that integrates Bayesian optimization with automated synthesis and automated property evaluation. The video below shows a conceptual diagram of this system.

At the center is a robotic arm for sample transport, surrounded by six satellite-like automated deposition and evaluation units arranged in a hexagonal pattern. The robotic arm allows for seamless transport of samples between all units. By using Bayesian optimization, the system can sequentially determine the next optimal synthesis conditions based on past deposition and evaluation results, thereby continuously optimizing conditions. A central computer manages the entire process of deposition, evaluation, and optimization, creating a fully automated, closed-loop materials discovery system.

Robotics Unit

This unit autonomously handles sample transport, deposition, and evaluation. The central robotic arm automatically accesses the satellite-like deposition and evaluation units. The system uses a sputter deposition method and can automatically perform deposition according to specified conditions, including substrate heating, atmospheric gas introduction, gas pressure control, plasma discharge, and shutter control. An automated probe stage is also integrated into the evaluation unit to automatically measure electrical conductivity.

Machine Learning Unit

This unit automatically collects measurement data and uses the statistical method of Bayesian optimization to analyze the collected big data, proposing the next set of experimental conditions to the robotics unit.

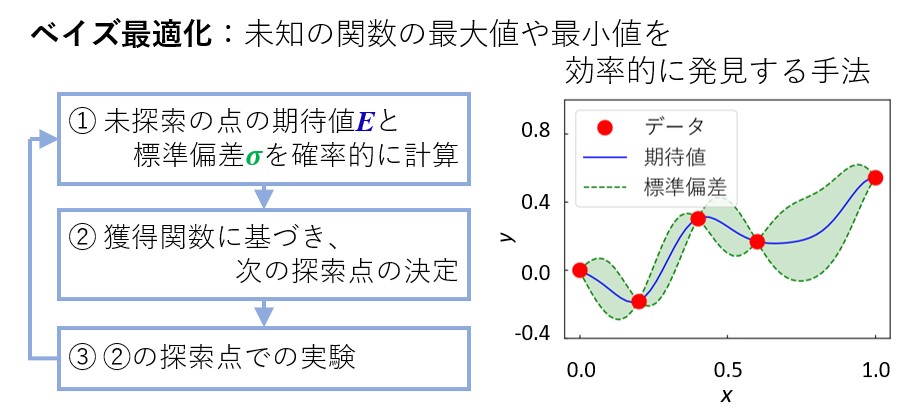

Bayesian Optimization

Bayesian optimization is a machine learning method that probabilistically and sequentially finds the maximum or minimum value of an unknown function based on existing data.

From the data already acquired, the system calculates the expected value (blue line) and confidence interval (green box) of un-explored points. Based on this result (the acquisition function), it determines the next point expected to yield a maximum or minimum, performs the experiment at that point, and updates the data. The cycle then repeats, using the newly updated data to recalculate the expected value and standard deviation. This cycle allows the system to efficiently find the maximum or minimum value.

This system allows experiments to be conducted continuously, even late at night or on weekends when researchers are not in the lab. It can perform 12 depositions and evaluations in 24 hours, which is approximately ten times the speed of a human-run experiment.